Cotton and Sorghum Farm

Energy Savings: 10% | Cost Savings: $7,182 | Capital Cost: $28,117 | CO2 Savings: 21.6 | Project Status: implemented

Industry:

Cotton, Grains and fodder

Location:

Darling Downs

Pump Type:

Bore

Irrigation Type:

Flood

Technology:

Irrigation and Pumps

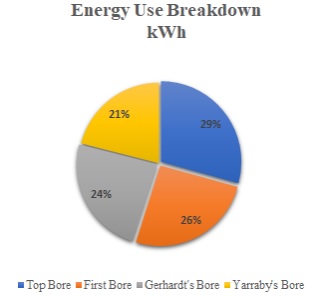

The four meters on site have 274,418kWh of energy consumed costing $58,373 per annum resulting in emissions of 252 tCO2-e.

To reduce energy consumption and costs onsite the audit recommended:

- Install two new 22kW efficient pumps.

- Four 20kw solar systems at the different pump sites.

The potential total energy savings determined from the audit were 105,373kWh, with costs savings of $29,131 and a reduction of 96.9 tCO2–e. The total capital expenditure required for these savings is $119,620 with a payback period of 4.7 years.

Table 1. Recommendations and Savings from the Energy Audit.

| Recommendation | Cost to Implement ($) | Energy savings (kWh) | Cost Savings ($) | Payback Period (Years) | Emission Savings (tCO2-e) |

| Replace pump one 22kW | 15,890 | 40,316 | 8,576 | 3.9 | 36.2 |

| Replace pump two 22kW | 15,890 | 25,275 | 5,376 | 3.0 | 23.2 |

| Four 20kW Solar PV | 87,840 | 39,782 | 15,087 | 5.8 | 36.4 |

| Total | 119,620 | 105,373 | 29,131 | 4.2 | 95.8 |

It is recommended to replace the top bore pump with a pump matched to the task requirements. Before replacing the pump there are four duty points to consider each with different friction losses, due to the irrigation design. With the replacement, pumping hours would be reduced by 35% and pump energy consumption by 50.2%. The second bore requires the same considerations due to the different friction losses, this replacement should reduce the pumping hours by 8% and the pump energy consumption by 35.9%. The payback period for the pumps is 1.9 and 3 years, respectively, with a reduction of 65,591kWh and costs of $13,952.

Collectively, by installing four 20kW solar systems at the separate NMIS consumption could be reduced by 39,782kWh and costs by $15,087.

Following the audit recommendations, the grower decided to replace the pump one. Post implementation savings and metrics have been calculated from the Measurement and Verification process, with achieved energy savings of 10% and cost savings of 12%, as follows.

Table 2. Actual savings from Implemented solution.

| Recommendation | Cost to Implement ($) | Energy savings (kWh) | Cost Savings ($) | Payback Period (Years) | Emission Savings (tCO2-e) |

| Replacement of pump one 22kW | 28,117 | 26,724 | 7,182 | 3.9 | 21.6 |

Table 3. Pre and Post Implementation energy consumption, costs, and energy productivity improvements.

| Metric | Pre-Implementation | Post-Implementation | Reduction % |

| Energy Consumption (kWh) | 274,418 | 247,694 | 10 |

| Energy Costs ($) | 58,373 | 51,191 | 12 |

| Energy Productivity (kWh/ha) | 572 | 516 | 10 |

An energy audit is a good investment

An energy audit is a great first step in moving a business towards a more efficient future by reducing energy use, costs, and Carbon emissions onsite.

The Energy Savers Plus Extension Program was delivered in by the Queensland Farmers' Federation with support and funding from the Queensland Department of Energy and Public Works.