Queensland Grains and Feedlot Farms

Energy Savings: 44% | Cost Savings: $41,109 | Capital Cost: $261,784 | CO2 Savings: 142 | Project Status: proposed

Industry:

Grains and fodder, Beef

Location:

Queensland

Pump Type:

Not applicable

Irrigation Type:

Not applicable

Technology:

Irrigation and Pumps, Lighting, Solar Power and Renewables, Batteries and Storage, Variable Speed Drives

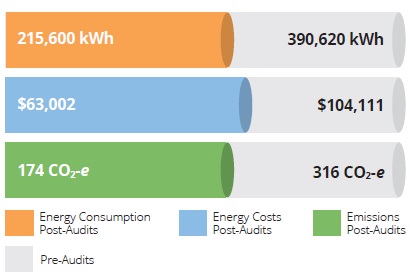

The total energy consumption from the measured areas on the 5 farms was 390,620kWh at an annual cost of $104,111, resulting in emissions of 316 tonnes of CO2-e.

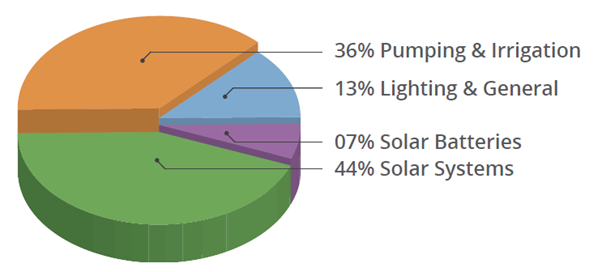

Opportunities: the main opportunities identified on the Grains and Feedlot farms include

- Pumping and Irrigation- Savings from Variable Speed Drive installation, pump replacements and maintenance and changes to irrigation design.

- Lighting and General- Replacement and retrofitting of lights with LEDs, infrastructure upgrades to facilitate efficiency gains and general management changes.

- Solar and Batteries– Grid-connected and standalone.

- Solar Systems- Ranging in size from 5-100kW.

Table 1. Technology Recommendations and Savings in the Grains and Feedlot Industry.

Recommendation |

Total | Energy Savings (kWh) | Cost Savings ($) | Capital Cost ($) | Average Payback (Years) | Emission Reduction (tCO2-e) |

Pumping and Irrigation Upgrades |

6 | 52,009 | 11,404 | 107,000 | 11 | 42 |

Lighting and General |

2 | 8,557 | 705 | 18,794 | 33 | 7 |

Solar and Batteries |

1 | 7,053 | 775 | 15,000 | 19 | 6 |

Solar Systems |

7 | 107,405 | 28,225 | 120,990 | 4.3 | 87 |

Total |

16 | 175,020 | 41,109 | 261,784 | 16.8 | 142 |

Total Recommendations |

665 | 7,459,015 | 2,817,342 | 12,784,670 | 6.85 | 6,042 |

Table 1 highlights the potential energy savings of 175,020kWh identified in the audits.

Including production benefits, a saving of $41,109 and an estimated 142 tonnes of CO2-e could be avoided per annum. At a capital cost of $261,784, the average payback was 116.8 years.

Additional value adding from the energy audits showed how an increase in water delivery, could increase production and profit with a reduction in energy consumed per unit of output.

Table 2. Pre and Post Audit Metrics.

Metric |

Pre-Audits | Post- Audits | Reduction (%) |

Energy Consumption (kWh) |

390,620 | 215,600 | 44 |

Energy Costs ($) |

104,111 | 63,002 | 39 |

Emissions (tCO2-e) |

316 | 174 | 44 |

As the installation of the recommendations is made within the industry, measurement and verification will be undertaken, and case studies will be updated to include the actual energy savings.

Energy Efficiency for your Industry and Business

An energy audit is a great way for a business to cut costs, reduce emissions and boost productivity.

The Energy Savers Plus Extension Program was delivered by the Queensland Farmers' Federation with support and funding from the Queensland Department of Energy and Public Works.