Sugar Cane and Horticulture Farm

Energy Savings: 31% | Cost Savings: $11,348 | Capital Cost: $17,000 | CO2 Savings: 25.5 | Project Status: proposed

Industry:

Sugarcane, Horticulture

Location:

Wide Bay Burnett

Pump Type:

Centrifugal

Irrigation Type:

Drip, Flood, Travelling gun

Technology:

Irrigation and Pumps, Variable Speed Drives

A mixed farming enterprise located in the Bundaberg region growing sugarcane, rockmelons, tomatoes and macadamia nuts could benefit from a recent Energy Savers Audit. The farm consists of 104 ha and is divided into three paddocks which are irrigated using three different pumps. Farming requires constant decision-making to maximise production and profit. Crops are often removed for the production of higher value products though sometimes the systems in place are outdated or do not account for these changes.

The current irrigation system is a mix due to development over time. Only one set of piping is operated at any time and therefore the specific piping for each individual operation contributes to friction losses. This allows the site to irrigate three different ways to satisfy the crop requirements for each paddock:

- Main flow through a 200 mm Sunwater supply to a 200 mm underground mainline for gravity feed furrow irrigation, which was practiced in the early years;

- Booster pump located in parallel with the gravity feed line to enable travelling gun operation on pump two.

- Diversion to a trickle irrigation filter bank which is the current mode of operation.

Energy consumption from the three pumping NMIs showed that a total 101,123kWh at a cost of $44,344 was used during the 2019 period.

Pump one has already been fitted with a new pump and 45 kW electric motor. Pump three operates the low–pressure drip system which will need to be upgraded to under tree sprinklers as the trees increase in size.

A recent energy audit showed how improving the current systems can lead to energy and cost savings by investing $17,000, the recommendations explored in the audit included:

- Install two Variable Speed Drives (VSD) on pump one and two.

- Install fit for duty pump to cover current and future irrigation requirements for the macadamias.

Table 1. Current cropping per paddock and energy savings from audit recommendations

| Recommendation | Cost to Implement ($) | Irrigation Type/ Crop/ Padlock Area | Energy Savings (kWh) | Emission Savings (tCO2-e) | Cost Savings ($) | Payback Period (Years) |

| Pump 1-Installation of VSD | 7,500 | Trickle

Sugarcane, Tomatoes 31.5 ha |

14,397 | 11.5 | 6,152 | 1.2 |

| Pump 2-Installation of VSD | 7,500 | Gravity trickle & Travelling gun

Sugarcane, Rockmelon, Tomatoes 39 ha |

13,399 | 10.7 | 4,418 | 1.7 |

| Pump 3-Installation of new pump fit for purpose | 2,000 | Low pressure drip

Sugarcane converting to macadamia 33.5 ha |

4,040 | 3.3 | 778 | 3.3 |

| Total | 17,000 | N/A | 31,836 | 25.5 | 11,348 | 1.5 |

Pump two is currently being choked back to reduce the pressure and match the travelling gun irrigator requirements. The high-pressure irrigation system operates approximately 16% of the time while the trickle irrigation 84 % of the time. Installation of VFD’s on pump one and two will allow the system to adjust to these two loads and result in an estimated combined reduction in annual energy consumption of 27,796 kWh.

Currently, pump three is best suited for the high-pressure travelling gun for growing sugarcane, which is incompatible with the future demand at the macadamia site. The new fit for purpose pump will deliver a higher volume of water, which was recommended in the audit to be a flow rate of 28.5 l/sec. This will meet moisture requirements while reducing energy by 4,040 kWh and cost per ML of water applied.

The farm has recently completed works to transition from obsolete farming tariffs and has moved to T33. The audit considered another move to T33 and T20. Although, costs would increase by roughly $456 for each of the three meters the move would avoid any interruptions in supply due to load control events, as T20 allows time of use and is an uninterrupted supply.

One highlight of the audit showed that to fix a bend located in the irrigation system, to reduce friction losses using pump two, would be costly exercise. As such a VSD has been recommended which allows the most cost–effective outcome for the business.

By installing all the recommendations in the audit, the business could reduce energy consumption by 31%, and costs by 25%, with carbon emission savings of 25.5 tCO2–e per year.

Table 2. Pre and post audit energy consumption, costs and energy productivity savings

| Metric | Pre-Audit | Post-Audit | Reduction (%) |

| Energy Consumption (kWh) | 101,123 | 69,287 | 31 |

| Cost ($) | 44,344 | 32,996 | 25 |

| Energy Productivity (kWh/ha) | 972 | 666 | 31 |

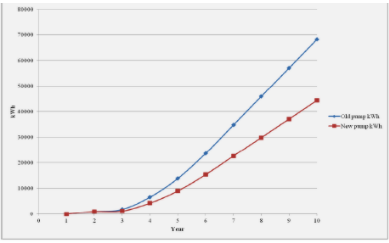

The long–term cost of establishing the crop increases with less efficient systems. The energy audit provided a long term forecast of the energy consumption and costs involved. Another factor the audit may consider is current rainfall patterns and future trends which may be shifting out of season.

Projected energy consumption from the old and new pump for macadamia establishment

An energy audit is a good investment

An energy audit is a great first step in moving a business towards a more efficient future by reducing energy use, costs and Carbon emissions onsite.

The Energy Savers Plus Extension Program was delivered in by the Queensland Farmers' Federation with support and funding from the Queensland Department of Energy and Public Works.